How to choose a steel structure grid processing manufacturer

In the field of construction engineering, steel structures are increasingly used. Their strengths, flexibility and environmental friendliness make them an ideal choice for many projects. When we face the critical decision of choosing a steel structure manufacturer, we need to consider many factors, especially in China, where the construction industry is booming and the steel structure industry is quite large.First of all, the Chinese steel structure market is highly competitive, and many manufacturers have their own strengths. When choosing, the manufacturer's production qualifications and experience are important indicators that cannot be ignored. A steel structure manufacturer with rich experience is often more advantageous in dealing with various complex engineering needs. For example, when dealing with the construction of large industrial plants or the construction of steel structures for landmark buildings, they can rely on their previous practical experience to accurately grasp the technical difficulties and key links in the construction to ensure the smooth progress of the project. For steel structure grid processing manufacturers, their professional experience in grid design and manufacturing is even more critical. There are many companies in China that focus on steel structure grid processing. When dealing with grid projects of large-span space structures, they can design grid solutions that are both stable and beautiful according to the functions and aesthetic requirements of different buildings.

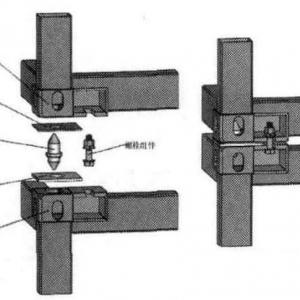

Secondly, product quality is the core element to measure the quality of steel structure manufacturers. High-quality steel structures should have high strength, good welding quality and precise dimensions. In China, reputable steel structure manufacturers will establish a strict quality control system, starting from the purchase of raw materials. For example, in the selection of steel, only steel suppliers that meet national standards and have stable quality are selected to ensure that each steel has excellent performance. In the production process, advanced processing equipment and exquisite welding technology are used to finely process each component of the steel structure to ensure its strength and precision. For the processing of steel structure grids, it is even more important to pay attention to the connection quality of the nodes and the stability test of the overall structure to ensure that the grid is safe and reliable when subjected to various loads.

In addition, the design and R&D capabilities of the manufacturer are also crucial. With the continuous development of the construction industry, the requirements for innovation and personalization of steel structures are getting higher and higher. Some leading steel structure manufacturers in China will invest a lot of resources in design and development. They can provide customized steel structure design solutions based on the unique needs of customers. Whether it is a uniquely shaped commercial complex or a complex functional stadium, these manufacturers can use advanced design software and technical means to create steel structure works that meet the requirements of architectural mechanics and are full of artistic beauty. For steel structure grid processing manufacturers, their design team needs to be proficient in spatial structural mechanics, and be able to optimize the structural form of the grid according to different building space and span requirements, improve the utilization rate of materials and the overall performance of the structure.

In addition, after-sales service is also an important part of choosing a steel structure manufacturer. In a market environment like China that focuses on engineering quality and reputation, excellent steel structure manufacturers will provide comprehensive after-sales service. Including installation guidance of steel structures, regular quality inspection return visits, and timely maintenance response when problems arise during use. For relatively complex structural forms such as steel structure grids, the after-sales service team needs to have professional technical knowledge and rich practical experience, and be able to quickly diagnose and solve possible structural problems to ensure the long-term safe use of buildings.

In short, when choosing a steel structure manufacturer in China, especially one involving steel structure grid processing, a comprehensive evaluation should be made from multiple aspects such as qualification experience, product quality, design and development capabilities, and after-sales service. Only in this way can we select an ideal partner who can provide high-quality steel structure products and all-round high-quality services for the project, ensuring the smooth implementation and long-term stability of the construction project.