Construction Technology for Spherical Grid Structure of Steel Structure Buildings

Exploring the Construction Technology of Spherical Grid Structure in Steel Structure BuildingsIn today's field of construction engineering, steel structure buildings stand out with their outstanding performance and unique aesthetic charm. Among them, the spherical grid structure has become the preferred structural form for many iconic buildings such as large sports venues, exhibition halls, airport terminals, etc. due to its efficient space utilization, strong load-bearing performance, and creative design. This article will provide a detailed analysis of the construction process for the spherical grid structure of steel structure buildings.

1、 Pre construction planning and preparation

Accurate planning and thorough preparation before construction are the cornerstones to ensure the smooth progress of the project. The design team carefully drew a detailed blueprint for the spherical grid structure design based on various factors such as the functional positioning of the building, geographical environment, and load requirements. The construction unit organizes professional technical personnel to thoroughly study the drawings, understand the design intent, and sort out the construction process and technical points. At the same time, a detailed investigation will be conducted on the construction site to ensure that the site is flat, solid, and meets the construction conditions. The material stacking area, processing area, and mechanical equipment parking area will be reasonably planned.

In the material procurement process, high-quality steel materials that meet national standards, including steel pipes, ball joints, and other main component materials, are strictly screened according to design requirements. Strictly inspect the quality of incoming materials, such as checking the material reports and mechanical performance testing reports of steel, reviewing the specifications, dimensions, and appearance quality of materials, and preventing unqualified materials from entering the construction site. In addition, fully equipped and high-performance construction machinery and equipment, such as cranes, welding machines, total stations, etc., should be properly debugged and maintained to ensure their stable operation during the construction process.

2、 Processing and manufacturing of grid components

According to the design drawings, precision machining of the components of the spherical grid structure is carried out in a professional processing workshop. For steel pipe components, advanced cutting equipment is used to cut according to the design length, ensuring a smooth cutting surface and accurate dimensions. The processing of ball nodes requires precision casting or forging processes to ensure their dimensional accuracy and mechanical properties. In the welding process, welding process parameters such as welding current, voltage, welding speed, etc. are strictly controlled and operated by experienced and certified welders to ensure uniform and firm weld quality, without defects such as porosity, slag inclusion, cracks, etc. After welding is completed, the weld seam shall be subjected to non-destructive testing, such as ultrasonic testing or radiographic testing, to ensure that the welding quality meets the specification requirements. The processed parts are numbered and marked one by one to facilitate efficient and orderly assembly work in the future.

3、 Grid assembly construction

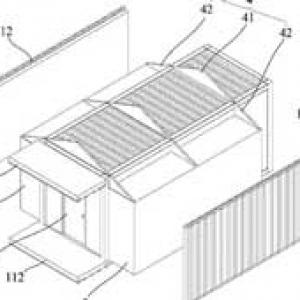

The assembly of the grid structure can be achieved by combining ground assembly with high-altitude bulk loading. Firstly, a stable assembly tire frame is built on the ground, and the components are gradually assembled into smaller units according to the numbering sequence, such as triangular cones, square pyramids, etc. During the assembly process, high-precision measuring instruments such as total stations are used to monitor and correct the geometric dimensions and axis deviations of the unit cell in real time, ensuring that the accuracy of the unit cell meets the design requirements. After a certain number of unit cells are assembled on the ground, a suitable tonnage crane is used to lift them to the design position for high-altitude bulk docking. When bulk loading at high altitude, it is necessary to reasonably determine the lifting point and lifting sequence, and take effective anti deformation measures, such as setting up temporary supports, adjusting the position of lifting points, etc., to ensure the structural stability of the grid during assembly and prevent excessive deformation.

4、 Welding and fastening operations for grid structures

After the overall assembly of the grid is completed, a comprehensive welding operation is carried out on the connection parts between each member. During the welding process, strictly follow the parameters determined in the welding process qualification report to ensure the strength and sealing of the weld seam. After welding is completed, conduct another weld quality inspection, including visual inspection and non-destructive testing, and promptly repair any defects found. For parts connected by bolts, use a professional torque wrench to tighten them according to the design requirements, and keep a record of the tightening to ensure the reliability and stability of the connection.

5、 Anti corrosion and Fire Protection Treatment of Grid Structure

To enhance the durability and safety of spherical grid structures, anti-corrosion and fireproof treatments are essential. Firstly, the surface of the grid should be thoroughly derusted, using methods such as sandblasting and shot blasting to achieve a rust removal standard of Sa2.5 or higher, providing a good foundation for subsequent coating construction. Then apply primer, intermediate coat, and topcoat, and choose the appropriate anti-corrosion coating system according to the environment and design requirements of the building to ensure uniform coating thickness and good adhesion, effectively preventing steel rusting and corrosion. For buildings with fire protection requirements, after the completion of anti-corrosion coating construction, fireproof coating should be applied according to the building's fire protection level requirements. The thickness and performance of the fireproof coating should comply with relevant specifications and standards to improve the fire resistance of the grid structure in the event of a fire, and to buy time for personnel evacuation and firefighting rescue.

6、 Quality acceptance and testing process

After the completion of the construction of the spherical grid structure, a professional quality acceptance team will be organized to conduct a comprehensive inspection and acceptance of the project quality based on relevant standards, specifications, and design documents. The inspection includes the structural dimensions, axis deviation, internal forces of members, weld quality, thickness and quality of anti-corrosion and fireproof coatings of the grid structure. Using static load tests, dynamic load tests, and other methods to verify the load-bearing capacity and structural performance of the truss, ensuring that it meets design requirements and is safe to use. Promptly rectify and handle any issues discovered during the acceptance process until the project quality fully meets the requirements before it can be delivered for use.

In summary, the construction process of spherical grid structure in steel structure buildings is a complex system engineering involving multiple links and technologies. Only by strictly controlling every aspect of the construction process and following scientific and reasonable construction techniques can we ensure the quality and safety of the spherical grid structure, and create a beautiful, durable, and high-performance steel structure building masterpiece.