Steel structure workshop canopy

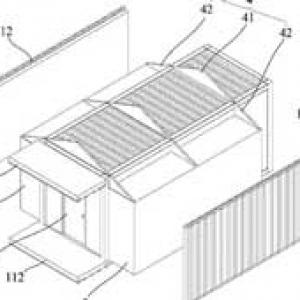

The core material of the Steel structure workshop canopy - steel, endows it with extraordinary strength and stability. Able to withstand the test of extreme weather such as strong wind, rainstorm and blizzard, and provide a strong "protective umbrella" for the equipment, raw materials and staff in the workshop. In some coastal areas, which are often hit by typhoons, the Steel structure workshop canopy, with its excellent wind resistance performance, effectively blocks the raging winds and ensures that everything in the workshop is safe and sound. Even in the cold north, facing the accumulation of heavy snow, it can stably support and will not easily deform or collapse.The flexibility of its design is a major highlight. Tailored according to the actual needs of different workshops, such as area, shape, height, etc. Whether it is a narrow workshop or a large open factory building, the steel structure workshop canopy can perfectly adapt to it. Moreover, in terms of design, it can also balance aesthetics and practicality, using simple and smooth lines to showcase the minimalist beauty of modern industry; It can also incorporate unique creative elements to showcase the personality and taste of the enterprise, becoming an important window for showcasing the company's image.

Durability is a prominent feature of the steel structure workshop canopy. High quality steel undergoes advanced anti-corrosion treatment, such as hot-dip galvanizing, which can form a dense protective film on the surface of the steel, effectively resisting the erosion of air, moisture, and various chemicals, greatly extending the service life of the canopy. Compared with traditional simple canopies, steel structure workshop canopies have a longer service life, reducing the cost investment and production interruption risk caused by frequent replacement of canopies, and providing a solid guarantee for the long-term stable operation of enterprises.

In terms of installation, the steel structure workshop canopy adopts a prefabricated construction method. After the components are prefabricated and processed in the factory, they are transported to the construction site for rapid assembly. This method not only shortens the construction period and reduces the difficulty of construction, but also effectively reduces pollution such as noise and dust on the construction site, which meets the requirements of modern environmental protection construction. For example, in some large-scale industrial projects with tight schedules, the rapid installation of steel structure workshop canopies can enable the workshop to be put into use as soon as possible, carry out production activities in advance, and win valuable time and economic benefits for the enterprise.

The steel structure workshop canopy is constantly innovating in terms of lighting and ventilation design. By setting up sun panels reasonably, energy consumption can be reduced. Utilize the position and size of ventilation openings to improve the air quality in the workshop and create a comfortable and healthy working environment.

In short, steel structure workshop canopies occupy an important position in the field of industrial construction due to their high strength, flexible design, strong durability, convenient installation, and good lighting and ventilation. It is a powerful assistant for enterprises to improve production efficiency, ensure asset safety, and shape a good image, contributing an indispensable force to the vigorous development of modern industry.