Steel structure workshop production daily report

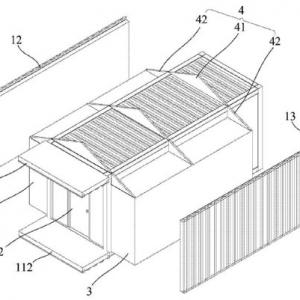

In the current booming construction industry, steel structures have become the core support for many large-scale projects due to their excellent strength and efficient construction speed. And every steel structure building, from blueprint to reality, cannot do without an efficient Steel structure workshop behind it. To enable you to have real-time and precise control over workshop dynamics.